-

Flexo Folder Gluer

-

Automatic Folder Gluer

-

Box Folder Gluer Machine

-

Flexo Printer Slotter

-

Flexo Printing Slotting Machine

-

Carton Making Machine

-

Corrugated Box Printing Machine

-

Corrugated Box Die Cutting Machine

-

Semi Automatic Box Stitching Machine

-

Automatic Strapping Machine

-

Flute Laminator Machine

-

Cardboard Production Line

-

Jordan CustomerThe machine not have any big shutdown since so many years, it's very stable and cost save.

Jordan CustomerThe machine not have any big shutdown since so many years, it's very stable and cost save. -

Thailand CustomerThe machine running very well till now, and service is good, we would like to work with them again, thank you!!!

Thailand CustomerThe machine running very well till now, and service is good, we would like to work with them again, thank you!!! -

Malaysia CustomerWithin last 2.5 years, we bought 3 machine from Toprint, they deserved our trust and we would like to work with them for long terms.

Malaysia CustomerWithin last 2.5 years, we bought 3 machine from Toprint, they deserved our trust and we would like to work with them for long terms.

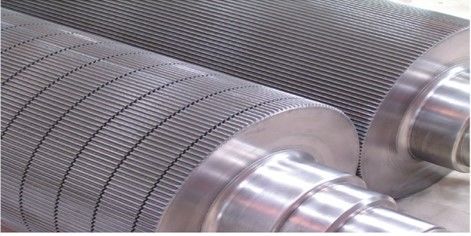

StarPack Corrugating Rollers 700kgs For Production Line CE Certification

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Corrugating Rollers | Model | Depends On Customer's Requirments |

|---|---|---|---|

| Type | Any Flute Available | Usage | 3 Ply Corruated Cardboard Production Line |

| Weight | 700kgs | Length | According To Customer's Requiremnts |

| Highlight | StarPack Corrugating Rollers,700kgs Corrugating Rollers |

||

Corrugating Rollers for Production line for 5 ply corrugated paper sheet 5-layer corrugated paper board production line

Products Description

A Complete Corrugating Board Production Line Includes The Following Machines:Mill Roll Stand, Pre-Heater, Splicer, Single Facer, Over Bridge, Multi-Pre-Heater, Glue Machine, Double Baker, Slitter Scorer, Cutoff, Stacker, And Ect.

Raw Paper Roll Feeded to The Roll Stand, After Heated And Moisture Adjusted By The Per-Heater, Raw Paper Will Go To The Single Facer, Corrugated By It, And Gluing Together With Another Raw Paper To Become Single Faced Corrugating Paper, Then Conveyed Through The Over Bridge, Re-Heated By Multi-Pre-Heater, After Glued By Glue Machine, Jointed By The Double Backer, Continuous Corrugating Board Comes Out.

After Slitting And Scorring By Slitter Scorer And Transverse Cutting By Cutoff, Corrugating Board With Different Sizes Are Produced. At Last, These Different Sizes Corrugating Board Will Be Stacked, Calculated.

Heating Way:Steam Heating.

Photos of Corrugating Rollers

![]()

![]()

![]()

Features

The precisely grinded gear roller is in drum shape by high hardness heat treatment, lathe, grinding of full automatic computer control.

The special treatment technique of gear surface hardening and plating hard chrome or nitriding guarantees the life and quality of corrugated roller(wheel).

Our company offers A,B,C,BC,E,D,F etc various dentiform products.

We can also design unique dentiform products as customer’s technical data

Make high quality tungsten carbide corrugated roller.

Technical Parameters

| Flute | A | B | C | BC | E | D | F |

| Shape | UV | UV | UV | UV | UV | UV | UV |

| Number | 34±2 | 48±2 | 38±2 | 34±2 | 44±2 | 92±2 | 125±2 |

| Height | 4.6-4.9 | 2.6-2.9 | 3.5-3.9 | 3.0-3.4 | 1.2-1.8 | 1.8-2.2 | 0.75-0.85 |