-

Flexo Folder Gluer

-

Automatic Folder Gluer

-

Box Folder Gluer Machine

-

Flexo Printer Slotter

-

Flexo Printing Slotting Machine

-

Carton Making Machine

-

Corrugated Box Printing Machine

-

Corrugated Box Die Cutting Machine

-

Semi Automatic Box Stitching Machine

-

Automatic Strapping Machine

-

Flute Laminator Machine

-

Cardboard Production Line

-

Jordan CustomerThe machine not have any big shutdown since so many years, it's very stable and cost save.

Jordan CustomerThe machine not have any big shutdown since so many years, it's very stable and cost save. -

Thailand CustomerThe machine running very well till now, and service is good, we would like to work with them again, thank you!!!

Thailand CustomerThe machine running very well till now, and service is good, we would like to work with them again, thank you!!! -

Malaysia CustomerWithin last 2.5 years, we bought 3 machine from Toprint, they deserved our trust and we would like to work with them for long terms.

Malaysia CustomerWithin last 2.5 years, we bought 3 machine from Toprint, they deserved our trust and we would like to work with them for long terms.

Servo Control Automatic Corrugated Carton Box Making Machine Labor Saving

| Place of Origin | Guangdong,CN |

|---|---|

| Brand Name | Toprint |

| Certification | CE Certificate, Patent Certificate |

| Model Number | TP-CR-0920/1224-FFG, |

| Minimum Order Quantity | 1 set |

| Price | Negotiation |

| Packaging Details | Steel Base with Carton and Film Wrapping |

| Delivery Time | 45-65 days |

| Payment Terms | L/C, T/T |

| Supply Ability | 3 Sets per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Servo Control High Folding Accuracy Cardboard Carton Box Making Machine Flexo Folder Gluer Automatic Strapping Machine | Type | For Make Corrugated Cartons |

|---|---|---|---|

| Voltage | 380V 50HZ Or Custom | Condition | Brand New |

| Service | Engineers Available To Service Machinery Overseas, Video Technical Support, Field Installation, Online Support, Commissioning And Training | Warranty | 1 Years After Installation |

| Automatic Type | Full Automatic, High Speed | Loading Port | Guangzhou Of China |

| Color | Custom | ||

| Highlight | 300Sheet/min Automatic Cardboard Box Making Machine,CE Automatic Cardboard Box Making Machine,Automatic Cardboard Box Making Machine |

||

Servo Control High Folding Accuracy Cardboard Carton Box Making Machine Flexo Folder Gluer Automatic Strapping Machine Full Set for Make All kind of Cartons High Efficiency

SUMMARY OF MACHINE

- Cardboard Box Making Machine, also called one-step cardboard box production line, is designed to process corrugated cardboard into products such as cartons, boxes, trays, displays etc.

- It can finish the process of Pre-feeding, feeding, printing, pre-creasing, creasing, slotting, die-cutting, gluing, counting and strapping at one time.

- The standard model of Cardboard Box Making Machine includes TP-CR-0920/1224-FFG, also the 0922/1228/1424/1632 be custom-made.

The Q6 featured with the functions as below marked by “√”.

| 1st Process | 2nd Process | 3rd Process | 4th Process | 5th Process |

| Order setting | Pre feeding | Feeding | 1-6 color Printing | Slotting |

| √ | √ | √ | √ | √ |

| 6th Process | 7th Process | 8th Process | 9th Process | 10th Process |

| Die cutting | Creasing | Gluing | Counting | Strapping |

| √ | √ | √ | √ | √ |

Specification

![]()

| Model | TP-CR-0920 | TP-CR-1224 | TP-CR-1628 |

| Size | 0920 | 1224 | 1628 |

| Max.Sheet Size (FxA) | 890x2000 | 1190x2400 | 1600x2800 |

| Skip Feed Size (FxA) | 1200x2000 | 1400x2400 | 1800x2800 |

| Min.Sheet Size (FxA) | 280x700 | 350x720 | 450x850 |

| Max.Printing Area (FxA) | 890x1960 | 1190x2360 | 1600x2760 |

| Top Speed(Sheet/min) | 300 | 250 | 180 |

| Economic Speed (sheet/min) | 150-250 | 120-220 | 100-160 |

| Min. Slotting Space-Reverse Knife (BxCxBxC) | 270x100x270x100 | 270x100x270x100 | 320x120x320x120 |

| Min. Slotting Space-Normal Knife (BxCxBxC) | 160x160x160x160 | 160x160x160x160 | 160x160x160x160 |

| Max. Slot Depth Size | 250 | 320 | 450 |

| Min. Box Height Size | 110 | 110 | 160 |

| Max. Die-Cutting Area | 850x1950 | 1150x2350 | 1530x2750 |

| Sheet Thickness | 1.5-11 | 1.5-11 | 1.5-11 |

| Thickness of Printing Plate | 7.2 | 7.2 | 7.2 |

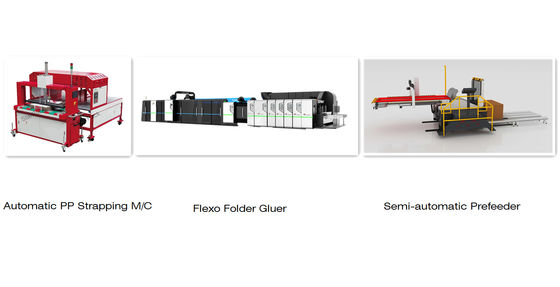

SEMI-AUTOMATIC PRE-FEEDER

![]()

- Pre-feeder is used to connect with automatic flexo printer machine.

- Conveyor arm length is motorized and adjusted freely.

- Back squarer is automatic along with conveyor.

FLEXO FOLDER GLUER

![]()

Feeding Unit

- Lead edge feeder with vacuum absorber.

- Upper Dust remover with brushers

- Sheet transfer with rubber pull rolls.

- Gap of feeding rollers, Side baffles are computerized with order managing.

Printing Unit

- Sheet transfer with vacuum box.

- Anilox roller with rubber roller inking or Anilox roller with Chambered doctor blade system for choosing.

- Quick replacing of rubber roller.

- Gap of anilox roller, printing drum, vacuum box and horizontal and vertical movement are computerized with order managing.

Slotting Unit

- Sheet transfer with rollers.

- 8-shafts rotation: Pre-creasing, Dual-Creasing, Single shaft slotting.

- All slotting knife holders connect with creasing rings and slotting knifes, synchronously moving in horizontal position.

- Gaps of creasers and slotting knifes, box height, registering and vertical moving are computerized with order managing.

Die cutting Unit

- Sheet transfer with rollers.

- Upper die cutting rubber roller is driven by independent frequency converter for line speed compensation.

- Shaft-head treated with lock, not welding, given strong capacity of bearing pressure.

- Gaps of feeding, registering and vertical moving are computerized with order managing.

FFG- Folder Gluer & Counter Ejector

- Top loading type Counter Ejector.

- Rolling wheel or auto flexo gluing system for choosing.

- Adjustment with servo motors.

- Gaps of Hold-Arm, Glue head and conveyor bracket are computerized with order managing.

- Central computer system controls whole units of machine.

AUTOMATIC PP STRAPPING MACHINE

![]()

- Cartons transferred by rolling wheel.

- Precision single piece strap track for positive control and exceptional feed reliability.

- Control system using ARM system.

- Strapping materials: PP

ADVANTAGES

- High capability: Maximum output up to 15000 per hours

- Labor saving: 3-4 workers for whole processes, to match with Auto Strapping machine.

- Easy Job: Order saving and quick changing by 5-10 min.

- Wide range application: Be used to agriculture, food, logistics and industrial packaging.

- Acceptability in Precision: More than 99% for printing accuracy and Up-Fold gap.

- Control with 9 sets of Servo Motor, Bosch Rexroth Brand origin from German.

Accuracy Assurance

| Feeding | ≤ ±1.5 mm | |

| Printing(4 colors) | ≤ ± 0.5 mm | |

| Slotting | ≤ ± 1.5 mm | |

| Die-cutting | ≤ ± 1.5 mm | |

| Up-fold gap(For FFG) | 3-layer | ≤ ± 2 mm |

| 5-layer | ≤ ± 3 mm | |

| “Fishtail” issue (For FFG) | 3-layer | ≤ ± 1.5 mm |

| 5-layer | ≤ ± 2 mm | |