-

Flexo Folder Gluer

-

Automatic Folder Gluer

-

Box Folder Gluer Machine

-

Flexo Printer Slotter

-

Flexo Printing Slotting Machine

-

Carton Making Machine

-

Corrugated Box Printing Machine

-

Corrugated Box Die Cutting Machine

-

Semi Automatic Box Stitching Machine

-

Automatic Strapping Machine

-

Flute Laminator Machine

-

Cardboard Production Line

-

Jordan CustomerThe machine not have any big shutdown since so many years, it's very stable and cost save.

Jordan CustomerThe machine not have any big shutdown since so many years, it's very stable and cost save. -

Thailand CustomerThe machine running very well till now, and service is good, we would like to work with them again, thank you!!!

Thailand CustomerThe machine running very well till now, and service is good, we would like to work with them again, thank you!!! -

Malaysia CustomerWithin last 2.5 years, we bought 3 machine from Toprint, they deserved our trust and we would like to work with them for long terms.

Malaysia CustomerWithin last 2.5 years, we bought 3 machine from Toprint, they deserved our trust and we would like to work with them for long terms.

Full Servo Control Auto Flute Laminator Machine 30KW High Speed Stable Running

| Feeding Way | Automatic Feeding | Name | Full Servo Control Automatic Flute Laminator |

|---|---|---|---|

| Function | Carton Box Folder Gluer | Service | Nstallation Service, Online Support, Video Support, Commissioning And Training |

| Product Name | Automatic Folder Gluer Machine | Automatic Type | Full Servo Control Automatic Hight Speed |

| Certification | CE Certificate, Patent Certificate | Voltage | 380V/50HZ Or Customs |

| Highlight | Auto Flute Laminator Machine,30KW Flute Laminator Machine,High Speed Flute Laminator |

||

Cardboard Laminating Machine Full Servo Control Automatic Flute Laminator with High Speed and Stable Running China made

SUMMARY OF MACHINE

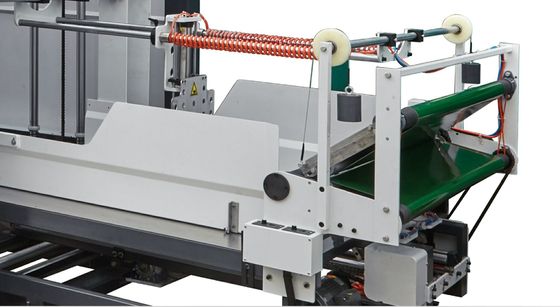

YB-1450HS/1650HS Cardboard Laminating Machine is also called HIGH SPEED LAMINATING MACHINE AND FLIP FLOP MACHINE, First the printed sheet and corrugated is laminated accurately and pressed through the conveyor, and then the laminated sheets be stacked based on the set amount in front and back side and slapped automatically and finally the stacked sheets come out automatically. The whole line achieves the high automation of the lamination.

MACHINE PHOTOS:

![]()

THE MAIN FEATURES:

- Automatic collecting, front and back placed stacking

- Save time and effort, simple and easy to learn

- Servo compensation positioning automatic tracking system

DETAILS OF EACH DEVICE:

- Bottom paper feeding: Use imported Servo motor electric controlling system, with Japan NITTA suction belt to make suction power inverter, and belt cleaned by water roller; Patented technology to ensure corrugate and cardboard goes out smoothly and simple operation.

- Top sheet feeding mechanism: equipped with high speed auto dedicated feeder, both paper lifting and feeding nozzle can freely adjust angle to the paper, to ensure that whether thick or thin paper can be delivered rapidly and smoothly.

- Electrical system: Designed in the accordance with European CE requirement, ensure machine stability, high efficiency and low failure. Using man-machine interface and PLC combination, display all the information, such as warning, error detect, failures, and operating speed, etc on the screen at a glance

- Pre-stack section: pre-stack pile of paper under the condition of non-stop, improve efficiency. The special design of the pre stack paper frame, save time and effort.

- Glue roller: Stainless steel roller, never rust, after narrowly grinding, guaranteed the minimum amount glue coated evenly. Down roller be cleaned by water roller.

- Transmission Part : Imported double toothed synchronous belt drive, equipped with a tensioning device to ensure the accuracy of the transmission, stable, low noise

- Positioning System: Using groups of photoelectric sensing bottom paper forward relative position, control top paper on both sides of the servo motor, independent compensation action, the top paper and bottom paper precision laminated.

- Flip flop system: Stacking the laminated sheets based on the set amount in front and back side automatically.

MACHINE PHOTOS:

![]()

THE MAIN PARAMETERS:

| Max sheet size | YB-1450HS | YB-1650HS |

| Min Sheet size | 1450×1450mm | 1650×1450mm |

| Top sheet thickness | 150-500g | 150-500g |

| Bottom sheet thickness | A/C/C/E/F (Corrugated paper),(four ply corrugated paper) | |

| Fitting precision | ±1mm | ±1mm |

| Air consumption | 1.2m3/min | 1.2m3/min |

| Measurement | 23.6*2.7*3M | 23.6*2.9*3M |

| Machine power | 30KW | 32KW |